Engine problem identified?

The one where we show that there are several problems with the engine refit!

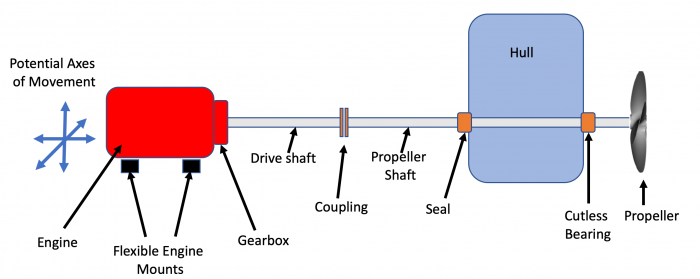

Engines move…To compensate or this movement, the engine in a boat uses 3 mechanisms.

1. Flexible engine mounts that compensate for the vibration of the engine as it rotates.

2. Very careful alignment between the drive shaft and the propellor shaft

3. A flexible coupling between the drive shaft and the propeller shaft that mitigates any vibration that is transferred from the moving engine.

These 3 elements work together to ensure that there is a minimum of movement from the engine to the propeller shaft and so there is a smooth vibration free force turning the propeller.

The recommendation for the Betamarine 70T is that there be flexible coupling in the drive train.

So I was quite surprised to find that there wasn’t one fitted to my yacht when she was updated recently.

I discovered all of this when sailing Eclipse after her refit. At 6 knots there was a very loud rotational noise form the gearbox and shaft. At 7 knots there was a significant noise and a regular knocking every revolution of the shaft. There was also a very visible vibration in the drive chain.

As I had already set off on a long planned cruise, I decided to drop in to a marine to have the problem assessed by a different engineer.

3 things became apparent.

1. The engine was out of alignment, both vertically and horizontally. Indeed the was no way the engine could have been correctly aligned as another problem existed. So the original yard cannot have completed the job properly.

2. There was no flexible coupling in the drive chain which was against the recommendations of the transmission builders.

3. There was a suspect noise in the gearbox that should have been detected by the original fitters.

The image above shows the drive change of a typical yacht engine.

As you can see, if everything is aligned and balanced, the propeller spins without incident.

If there is movement in the engine that will transfer to the drive chain and if this is compensated there will be stress and friction at the point where the propeller shaft enters the stern tube.

If this continues for any period, the bearing and shaft will be damaged.

Here is a short clip of the drive chain in neutral, under sail and the sound it makes. You can see why I was so concerned. You can see the vibration and clearly the noise is a concern!.

Remember this is the engine in neutral and turned off. The hydraulic gearbox means that even putting the transmission in reverse the propeller continues to turn.

And here is picture of the result of an incorrectly fitted engine and gearbox. As you can see, there is a certain shine to an older propeller shaft and scoring and clear wear as the vibration and lack of alignment has forced the shaft against the bearing.

EPIC FAIL!

You trust a team to look after your refit. You pay them well and still there seems to be no guarantee of a quality job. And despite several attempts to get some support they still haven’t been in touch.